A magnetic contactor is a device that is powered by magnetism. Used to open and close the contacts in the motor control circuit, may also be called a magnetic switch or a contactor.

It is a device that is very often used in industry. Commercial, large industries are very much dependent on this device. Through it, we can easily control heavy loads such as high-capacity motors.

Basically, a magnetic contactor works on the same principle as a relay, connecting and disconnecting electricity. The actuators are similar, this device uses a coil, which when an electrified coil creates a magnetic field.

This magnetic field can control the contacts that exist in magnetic contactors. What makes magnetic contactors different from relays is, magnetic contactors have main contacts, namely contacts that may be made specifically to control a motor phase.

Magnetic Contactor Working Principle

When an electric current flows to the magnetic field coil located in the center leg of the coil core. This will create a magnetic contactor in which the magnetic field forces overcome the spring force to cause the steel core to move down in this state (ON).

Two sets of contactors will change the operating condition,

- The normally closed (NC) contactor will open the contact point circuit and

- The normally open contactor (NO) will open the contact circuit, connect the circuit of the contact point when there is no current flowing to the coil, all contactor magnetic fields.

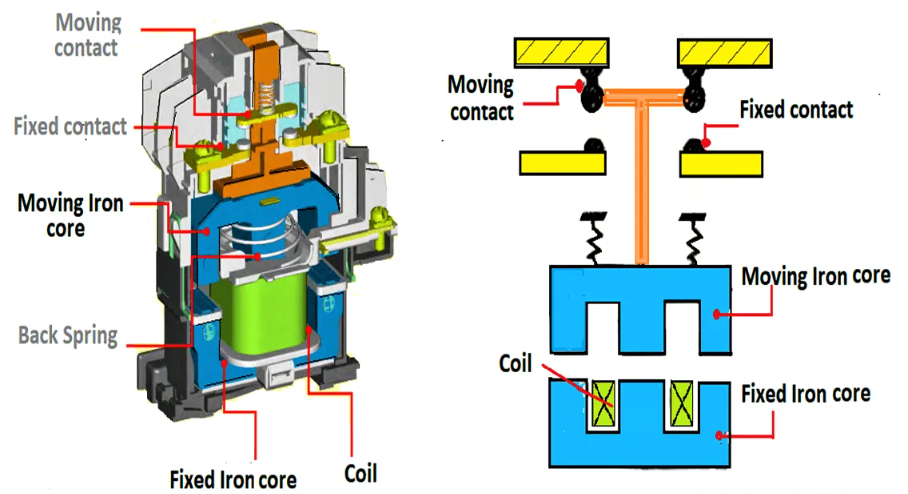

The major structure of the magnetic contactor

The basic elements of magnetic contactors are as follows.

1. Iron Core

The iron core is divided into two parts:

Fixed Core

It becomes an electromagnet when the coil is energized.

Moving Core

When the coil gets energized, a magnetic contactor is closed and it makes the moving core slide into the fixed core.

2. Coil

The coil is powered to pull the main contacts close, auxiliary contacts use the power of that coil to operate.

3. Contact

There are mainly two types available.

Main Contact

The main contact also known as “the main Contact”, is used in the power circuit to connect the electrical system to the load.

The main contacts are designed for hundreds or more ampacity and auxiliary contacts are for tens or less.

Auxiliary Contact

Auxiliary Contact is used with the “auxiliary contact control circuit” as a secondary switching. The contacts may be normally open (NO) or normally close (NC). Normally open are open when the contactor is de-energized, whereas normally closed are the opposite. The auxiliary contacts are allowed to pass small currents, used to show the status of the main contacts. In other words, it provides an interface to the control system.

Types of Magnetic Contactors

Magnetic contactors are divided mainly into two categories

1. AC contactor.

2. DC contactor.

AC contactor

Contactors that are used with AC power are divided into 4 types according to the nature of the load and its use is as follows:

AC 1 magnetic contactor -This type of contactor is helpful in resistive loads such as heater and electrical furnace, and non-inductive or slightly inductive loads, which means the load’s power factor lies between 0.95 and 1.

AC 2 magnetic contactor -For starting of slip-ring motors. Suitable for use with retractable loads as a slip ring motor. They mostly prefer high torque current applications.

AC3 magnetic contactor -Suitable for starting and stopping loads at the motor is up to a speed of a squirrel cage motor. This type of contactor can withstand of high current continuously. Example – Elevators, lifts.

AC4 magnetic contactor -Suitable for frequent starting-stop motor circuit jogging and the reversal of the squirrel-cage motor rotation. Also used in rapid start/stop. Example-Cranes.

DC contactor

The following are the types of DC contactors.

DC-1 magnetic contactor -Suitable for inductive and slightly non-inductive loads, resistance furnaces, heaters.

DC-2 magnetic contactor -Shunt motors, starting, plugging, inching, dynamic breaking.

DC-5 magnetic contactor -Series-motors, starting, plugging, inching, dynamic braking.

Advantages of Magnetic Contactors

Advantages of using relays and magnetic contactors when compared with other switches

1. Provides high safety for operators

2. Provide ease of control

3. Economical compared to manual controls

4. Controllable with an automatic device or a remote-control operation is possible.

Applications of Magnetic Contactors

The following are some of the applications of magnetic contactors.

Magnetic Motor Starter

It is an electrically operated switch (contactor) that comprises motor overload protection. Magnetic motor starters are similar to contactors, additionally, they have an overload attached to them.

Overloads have heaters or electronic overloads, which sense excessive current flow to the motor.

The magnetic motor starter is a magnetic contactor plus overload relay.

Lighting Control Contactor

It is being used for remote or local switching of relatively large mercury, fluorescent, or tungsten, or even in LED lighting load centralized ON/OFF control.

Reference: Fundamentals and D-C machines By Michael Liwschitz-Garik, Clyde Colburn Whipple.